Electric bikes (e-bikes) have revolutionized urban commuting and recreational cycling, offering a sustainable and efficient alternative to traditional transport. At the heart of every e-bike is its motor system, which significantly impacts performance, efficiency, maintenance, and ride experience. For engineers, enthusiasts, or anyone keen to understand the tech behind e-bikes, choosing between hub motors and mid-drive motors is a critical decision. This guide breaks down the engineering fundamentals, pros and cons, and real-world applications of both motor types to help you make an informed choice.

What Are E-Bike Motors?

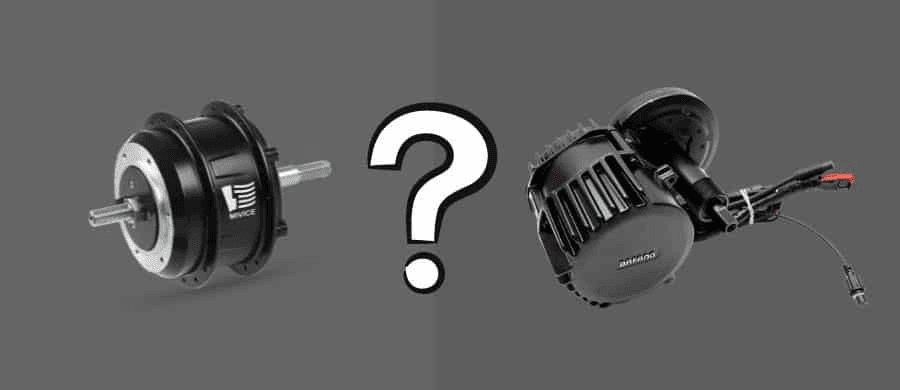

E-bike motors assist the rider by providing additional power when pedaling. They are classified mainly into two types based on their placement and mechanical integration:

- Hub Motors: Located in the center of either the front or rear wheel, driving the wheel directly.

- Mid-Drive Motors: Mounted near the bike’s bottom bracket, powering the drivetrain through the bike’s chain and gears.

Hub Motors: Simplicity and Direct Drive

How Hub Motors Work:

Hub motors are built into the wheel hub and generate torque directly on the wheel rim. They come as geared or gearless (direct drive) motors. The motor spins the wheel independently of the bike’s gears.

Engineering Highlights:

- Simpler mechanism with fewer moving parts.

- Independent of the drivetrain, allowing ease of installation or retrofit.

- Typically found in front or rear-wheel configurations.

Advantages of Hub Motors:

- Ease of Maintenance: Isolated from the bike’s drivetrain, resulting in less wear on gears and chains.

- Quieter Operation: Geared hub motors can be very quiet.

- Cost-Effective: Generally, hub motors are cheaper and more common in entry-level e-bikes.

- Good for Flat Terrain: Effective for steady rides on level ground.

Disadvantages of Hub Motors:

- Limited Hill Climbing: Because they don’t leverage the bike’s gears, they can struggle on steep hills.

- Heavier Wheels: The motor adds mass to the wheel, which can affect handling.

- Less Efficient Energy Use: Energy usage may be less optimized compared to mid-drive systems, especially on varied terrain.

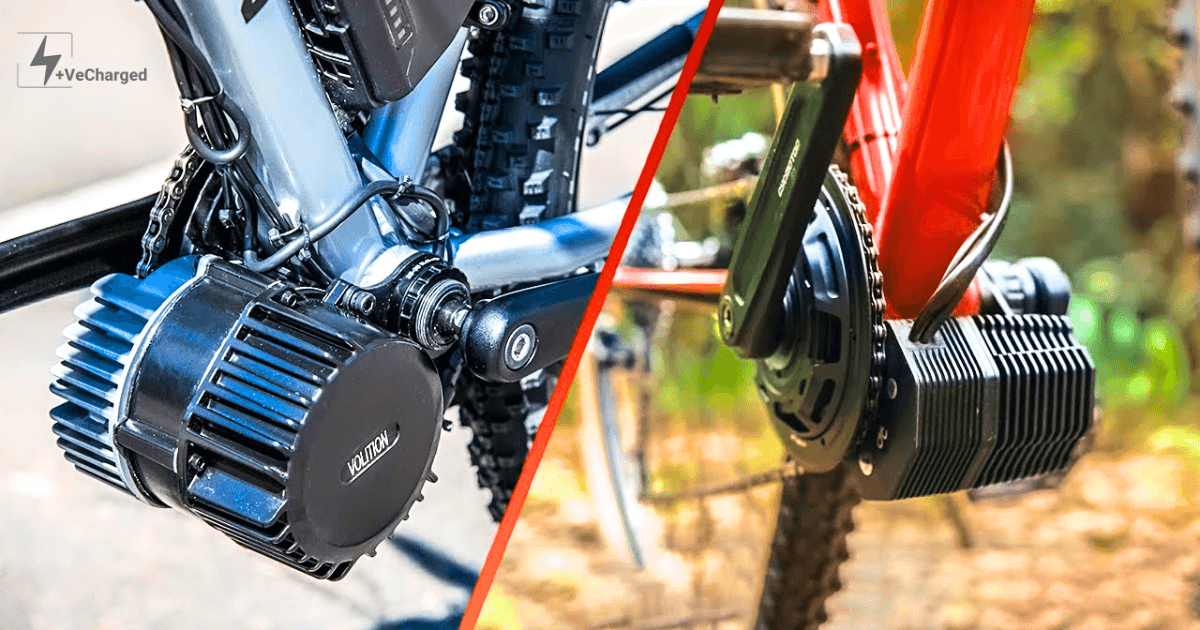

Mid-Drive Motors: Optimal Power Transmission

How Mid-Drive Motors Work:

Mid-drive motors connect to the bike’s crank and deliver power through the chain to the rear wheel. This system uses the bike’s existing gears for optimized torque and efficiency.

Engineering Highlights:

- Power output is multiplied by the bike’s gear ratios.

- Central motor placement helps with weight distribution.

- Requires a more complex installation and integration with the bike’s drivetrain.

Advantages of Mid-Drive Motors:

- Superior Hill Climbing: Leveraging gears gives better torque control and power on inclines.

- Efficiency: Motor runs at optimal RPM, increasing battery life and range.

- Balanced Weight: Central positioning improves bike stability and handling.

- Easier Maintenance for Wheels: Wheel hubs are free of motors, easier to repair or replace.

Disadvantages of Mid-Drive Motors:

- Drivetrain Wear: The added torque can accelerate wear on the chain and gears.

- Higher Cost: More complex technology usually means a higher price point.

- Installation Complexity: Requires a quality bottom bracket area and drivetrain compatibility.

Side-by-Side Comparison

| Feature | Hub Motor | Mid-Drive Motor |

|---|---|---|

| Location | Front or rear wheel hub | Near bottom bracket/chainring |

| Power Delivery | Direct wheel spinning | Through bike’s gears and chain |

| Weight Distribution | Heavier wheel, uneven distribution | Centralized, better balance |

| Hill Climbing | Less effective | Excellent, uses gear multiplication |

| Efficiency | Good for flat terrain | More efficient across varying terrain |

| Maintenance | Easier wheel repair, no drivetrain wear | Increased chain/gear wear |

| Cost | Generally lower | Generally higher |

| Noise | Quieter (especially geared hubs) | Slight mechanical noise from drivetrain |

| Ride Feel | Can feel less natural | Feels more like traditional cycling |

Practical Considerations for Dutch and Urban Riders

For commuters in regions like the Netherlands, where terrain is mostly flat but security and comfort are major concerns, both motor types have merits. Hub motors provide a low-maintenance, quiet ride ideal for city cruising, while mid-drive motors offer versatility for mixed urban and off-road conditions.

Conclusion: Which Motor Is Right for You?

- Choose a hub motor if you prioritize affordability, low maintenance, and mostly flat commuting.

- Opt for a mid-drive motor if you want better performance on varied terrain, longer range, and don’t mind higher upfront costs or drivetrain maintenance.

Read further on related topics at vecharged.com to deepen your e-bike expertise, including guides on e-bike maintenance, accessories, and the latest models suitable for Dutch riders.

This engineer’s guide aims to clarify the mechanical and practical distinctions between e-bike motor systems, helping you make a choice that best fits your commuting style and technical preferences for 2025 and beyond.

An Engineer’s Guide to E-Bike Motors: Hub vs. Mid-Drive

Electric bikes (e-bikes) have revolutionized urban commuting and recreational cycling, offering a sustainable and efficient alternative to traditional transport. At the heart of every e-bike is its motor system, which significantly impacts performance, efficiency, maintenance, and ride experience. For engineers, enthusiasts, or anyone keen to understand the tech behind e-bikes, choosing between hub motors and mid-drive motors is a critical decision. This guide breaks down the engineering fundamentals, pros and cons, and real-world applications of both motor types to help you make an informed choice.

What Are E-Bike Motors?

E-bike motors assist the rider by providing additional power when pedaling. They are classified mainly into two types based on their placement and mechanical integration:

- Hub Motors: Located in the center of either the front or rear wheel, driving the wheel directly.

- Mid-Drive Motors: Mounted near the bike’s bottom bracket, powering the drivetrain through the bike’s chain and gears.

Hub Motors: Simplicity and Direct Drive

How Hub Motors Work:

Hub motors are built into the wheel hub and generate torque directly on the wheel rim. They come as geared or gearless (direct drive) motors. The motor spins the wheel independently of the bike’s gears.

Engineering Highlights:

- Simpler mechanism with fewer moving parts.

- Independent of the drivetrain, allowing ease of installation or retrofit.

- Typically found in front or rear-wheel configurations.

Advantages of Hub Motors:

- Ease of Maintenance: Isolated from the bike’s drivetrain, resulting in less wear on gears and chains.

- Quieter Operation: Geared hub motors can be very quiet.

- Cost-Effective: Generally, hub motors are cheaper and more common in entry-level e-bikes.

- Good for Flat Terrain: Effective for steady rides on level ground.

Disadvantages of Hub Motors:

- Limited Hill Climbing: Because they don’t leverage the bike’s gears, they can struggle on steep hills.

- Heavier Wheels: The motor adds mass to the wheel, which can affect handling.

- Less Efficient Energy Use: Energy usage may be less optimized compared to mid-drive systems, especially on varied terrain.

Mid-Drive Motors: Optimal Power Transmission

How Mid-Drive Motors Work:

Mid-drive motors connect to the bike’s crank and deliver power through the chain to the rear wheel. This system uses the bike’s existing gears for optimized torque and efficiency.

Engineering Highlights:

- Power output is multiplied by the bike’s gear ratios.

- Central motor placement helps with weight distribution.

- Requires a more complex installation and integration with the bike’s drivetrain.

Advantages of Mid-Drive Motors:

- Superior Hill Climbing: Leveraging gears gives better torque control and power on inclines.

- Efficiency: Motor runs at optimal RPM, increasing battery life and range.

- Balanced Weight: Central positioning improves bike stability and handling.

- Easier Maintenance for Wheels: Wheel hubs are free of motors, easier to repair or replace.

Disadvantages of Mid-Drive Motors:

- Drivetrain Wear: The added torque can accelerate wear on the chain and gears.

- Higher Cost: More complex technology usually means a higher price point.

- Installation Complexity: Requires a quality bottom bracket area and drivetrain compatibility.

Side-by-Side Comparison

| Feature | Hub Motor | Mid-Drive Motor |

|---|---|---|

| Location | Front or rear wheel hub | Near bottom bracket/chainring |

| Power Delivery | Direct wheel spinning | Through bike’s gears and chain |

| Weight Distribution | Heavier wheel, uneven distribution | Centralized, better balance |

| Hill Climbing | Less effective | Excellent, uses gear multiplication |

| Efficiency | Good for flat terrain | More efficient across varying terrain |

| Maintenance | Easier wheel repair, no drivetrain wear | Increased chain/gear wear |

| Cost | Generally lower | Generally higher |

| Noise | Quieter (especially geared hubs) | Slight mechanical noise from drivetrain |

| Ride Feel | Can feel less natural | Feels more like traditional cycling |

Practical Considerations for Dutch and Urban Riders

For commuters in regions like the Netherlands, where terrain is mostly flat but security and comfort are major concerns, both motor types have merits. Hub motors provide a low-maintenance, quiet ride ideal for city cruising, while mid-drive motors offer versatility for mixed urban and off-road conditions.

Conclusion: Which Motor Is Right for You?

- Choose a hub motor if you prioritize affordability, low maintenance, and mostly flat commuting.

- Opt for a mid-drive motor if you want better performance on varied terrain, longer range, and don’t mind higher upfront costs or drivetrain maintenance.

Read further on related topics at vecharged.com to deepen your e-bike expertise, including guides on e-bike maintenance, accessories, and the latest models suitable for Dutch riders.

This engineer’s guide aims to clarify the mechanical and practical distinctions between e-bike motor systems, helping you make a choice that best fits your commuting style and technical preferences for 2025 and beyond.

Suhas Shrikant is the founder of Vecharged and an engineering enthusiast specializing in high-power off-grid solar systems. He has designed and built over a dozen custom systems and uses his hands-on, field-tested experience to create Vecharged’s expert guides and reviews.

[…] An Engineer’s Guide to E-Bike Motors: Hub vs. Mid-Drive […]